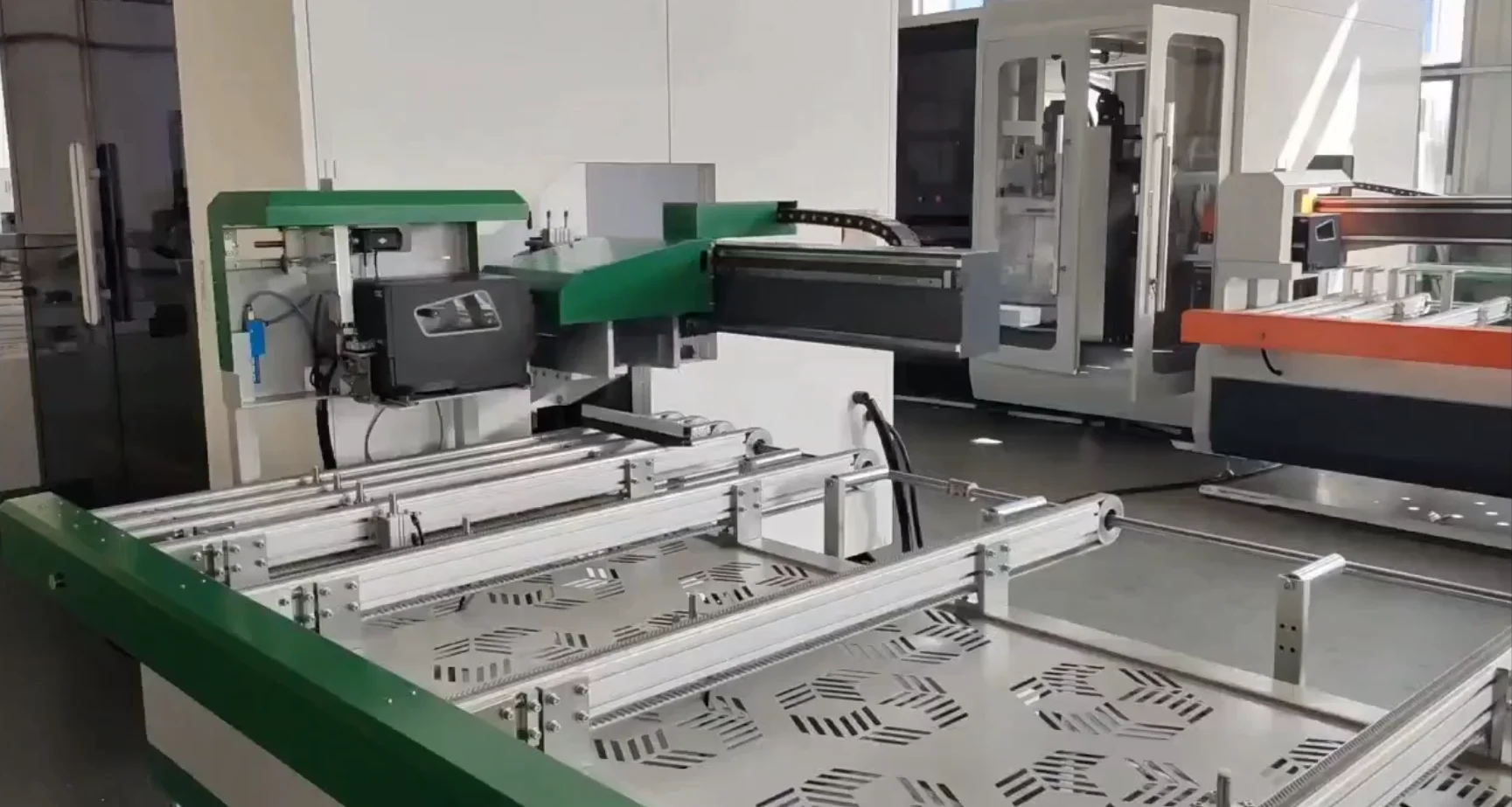

- 1. Professionally used for cutting aluminum profiles, single-sided laser drilling and double-sided laser engraving.

- High efficiency: 45° saw blade servo feed, high efficiency.

- Range: 1000 – 6600mm, Profile width: 150mm, Profile height: 150mm

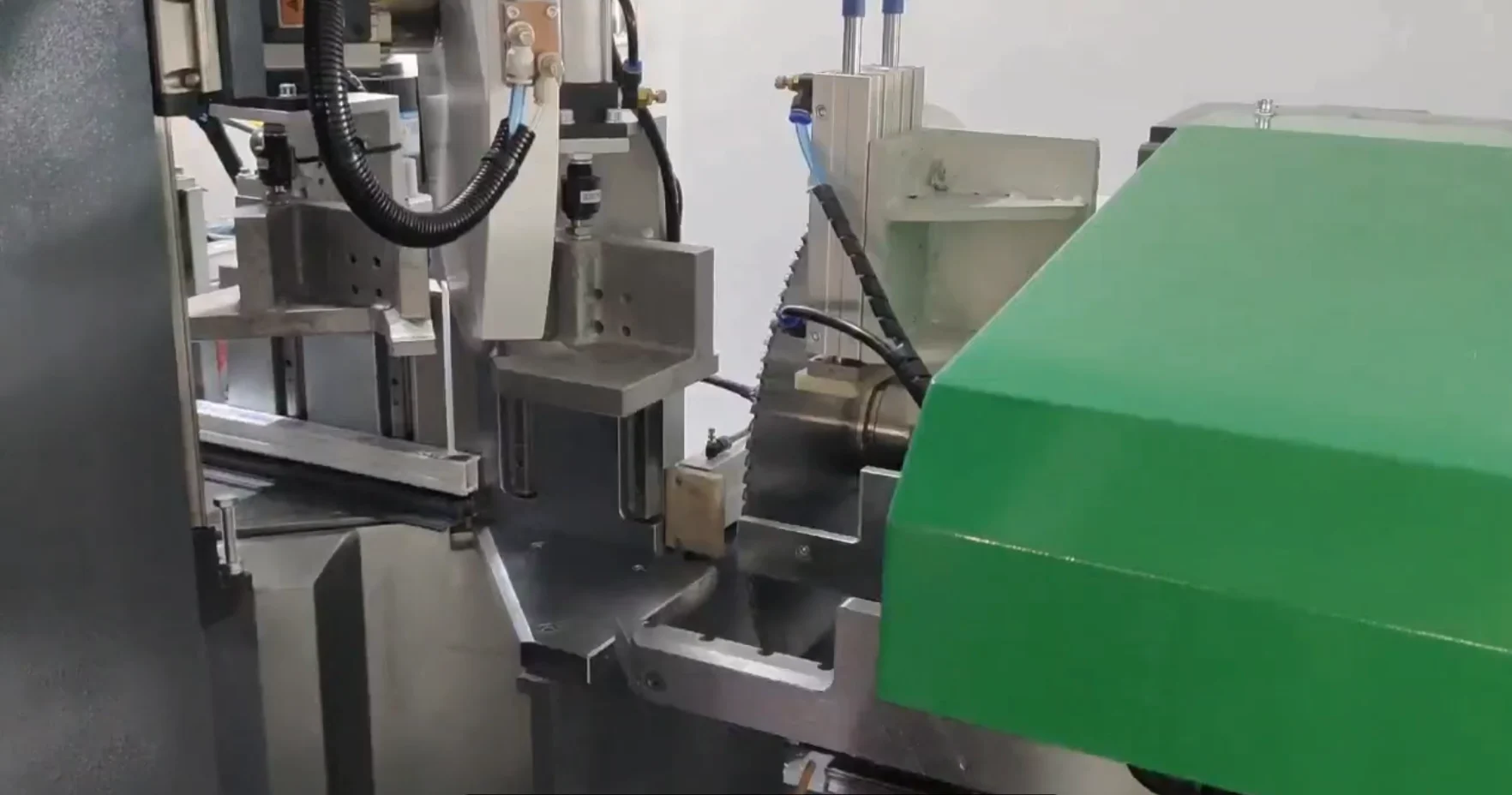

- High power: Equipped with a 3KW direct-connected motor. The efficiency of cutting profile materials with insulation is 30% higher than that of a 2.2KW motor.

- High precision: The overall cast-type cutting mechanism has three fixed angles: 2 at 45° + 1 at 90°. The cutting length error is ±0.1mm, the flatness of the cutting profile is ≤0.10mm, and the cutting angle error is ±5′.

- It can perform bilateral laser engraving and the positioning is accurate.

- Laser processing has high efficiency: The rear side is equipped with a laser cutting device. The power can be automatically adjusted according to the wall thickness of the profile. The cutting quality is excellent. According to the process requirements, it can automatically switch between the engraving and cutting states to perform engraving or cutting.

- The front side is equipped with a dedicated laser engraving machine, which can perform laser engraving on both sides simultaneously, achieving high efficiency.

- Dumb operation: No skilled workers required, no need to adjust the manipulator (it can automatically rotate to hold irregular materials), no need to consider the cross-section of the profile (Z-shaped fans, conversion frames are fine), no need to custom-make the template, no need to consider the height of the profile.

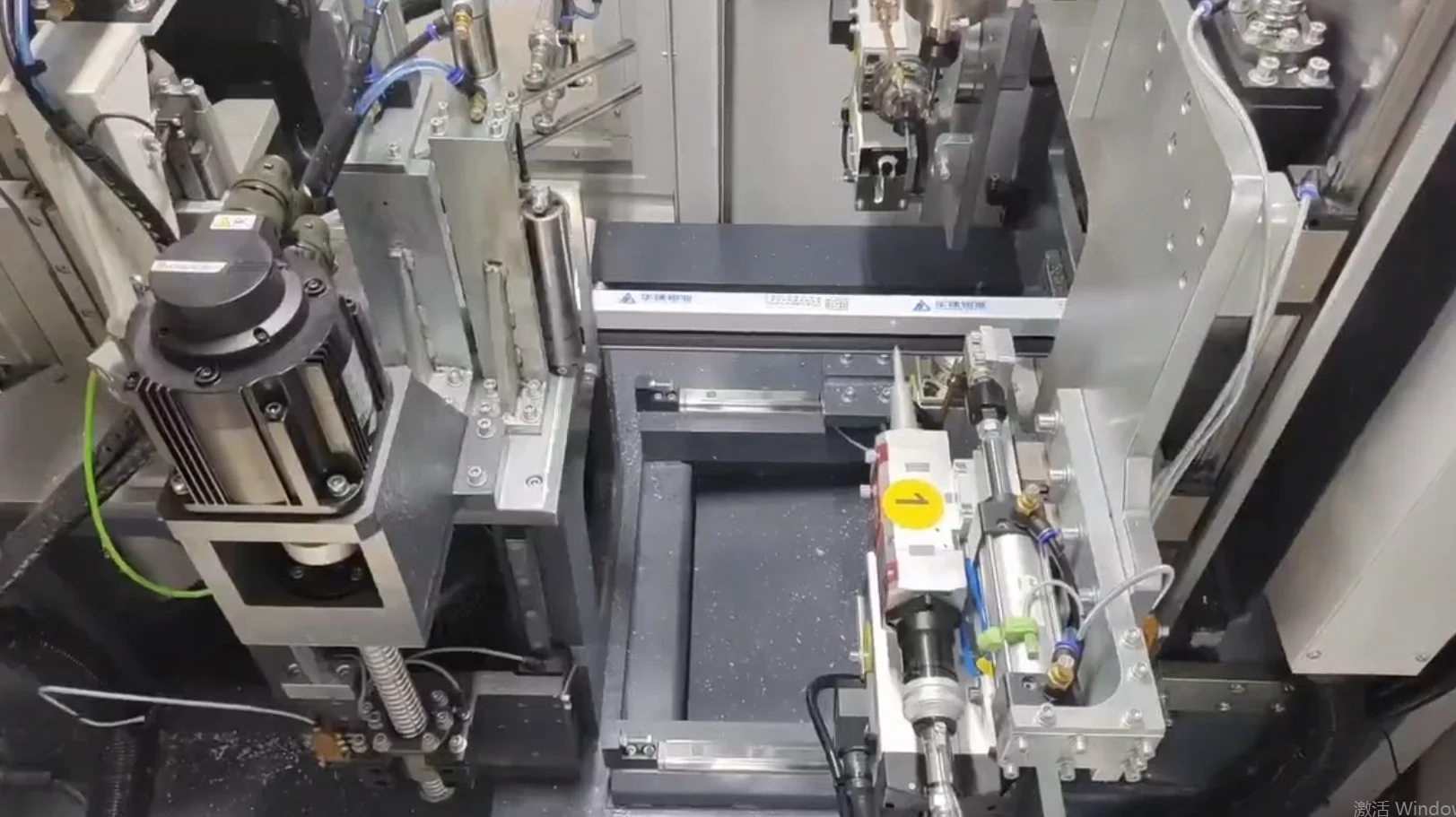

- High degree of automation: One ordinary worker can operate it. It can place 7 profiles at a time, and automatically complete the feeding, cutting and discharging processes.

- Intelligence: The feeding system is fully servo-controlled. It can intelligently recognize the data of the profiles (height, wall thickness), and intelligently adjust the processing parameters (feed speed, feed position)

- 0 Error: The equipment is equipped with an error prevention mechanism.

Data import method:

1、Software integration: Connected to ERP software, such as: Klaes, Jopps, Mentoo Cloud, Zheyi, Xin Gele, etc.;

2、Network/USB drive import: Just follow the existing cutting sheet format of the factory.;

3、manual input

13. Equipped with an automatic chip-discharging machine (for metal shavings) and an automatic dust-collecting device, it reduces the cleaning frequency and enhances the work efficiency.

14. Safety: Gas-electric protection device, mechanical protection device, ensuring safe production.

15. Standardly equipped with a tool life management system, which automatically alerts for the need to sharpen or replace the saw blades.

16. Standardly equipped with automatic maintenance reminder function, it can proactively detect potential equipment problems and enhance the equipment utilization rate.

17. Standard capacity statistics, equipment status time statistics, real-time monitoring, controllable delivery time, reduced inventory, and increased utilization of capital flow.

18. It has remote service capabilities (maintenance, servicing, training), which saves service time, reduces downtime, and lowers the factory’s reliance on skilled workers.