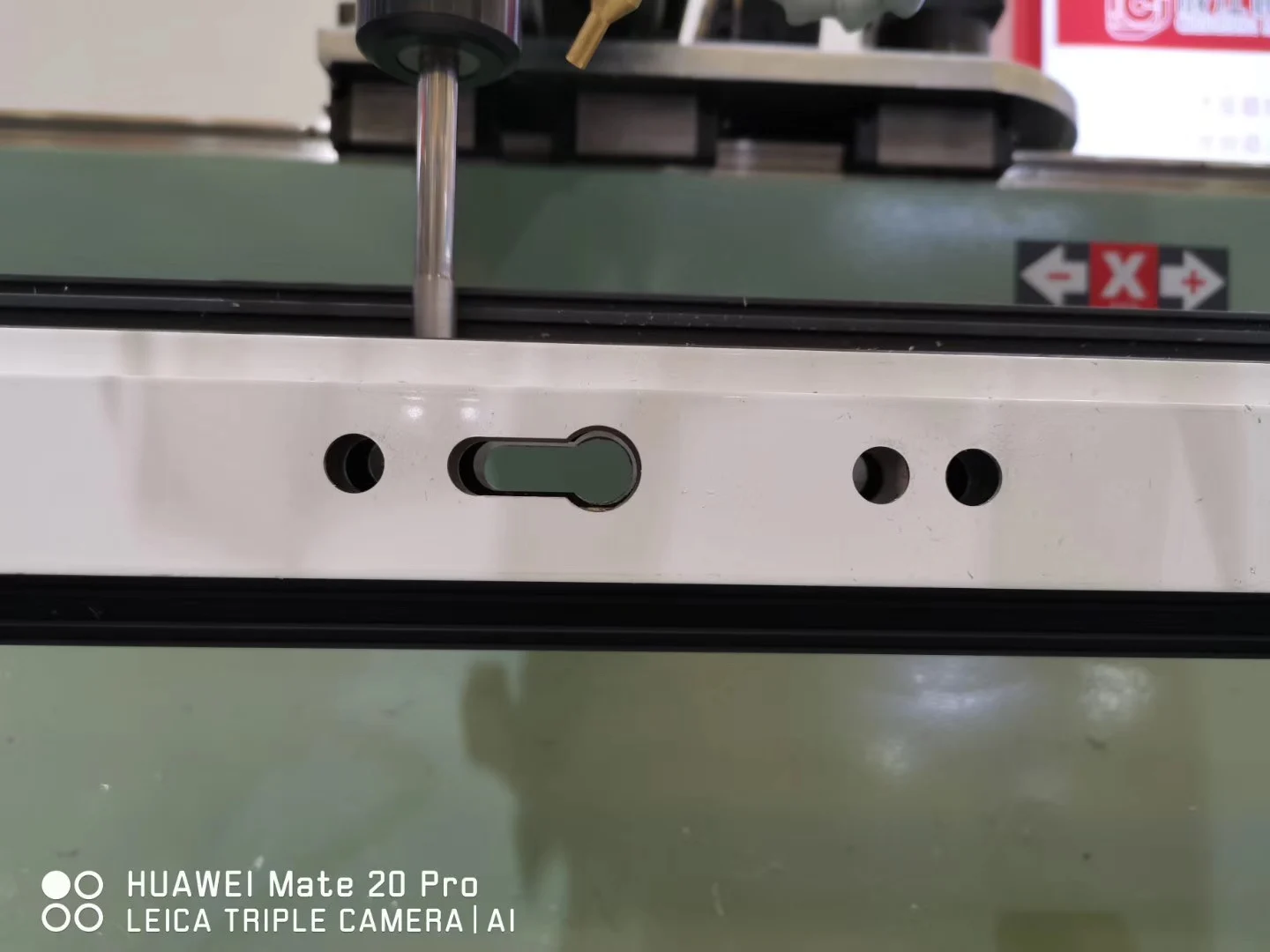

1. It is suitable for precision machining of various holes, wedge grooves, water ports and other processes of aluminum doors and windows or curtain wall profiles.

2. The intelligent numerical control system and simple and intuitive man-machine interface make the operation more convenient and quick, and all the machining

processes are intelligently and automatically completed without manual intervention, with high working efficiency, high machining accuracy, safety and

reliability.

3. Equipped with a three-station tool magazine, the tool can be changed automatically in the process of machining, which can realize milling with different apertures.

4. Fully enclosed structure design, high-end atmosphere, clean and environmental protection, to ensure the safety of operators.

5. The rotatable table can be switched between-90°, 0° and +90° positions, so that the milling of all the holes on three surfaces can be completed by clamping at one

time.

6. Adopt gantry structure design, with high strength of the lathe bed, good rigidity of the whole machine, stable and reliable performance and high working

precision. All actions are realized by servo motor and pneumatic system.

7. Adopt imported high-speed electric spindle, which has stable rotation, low noise and strong cutting ability.