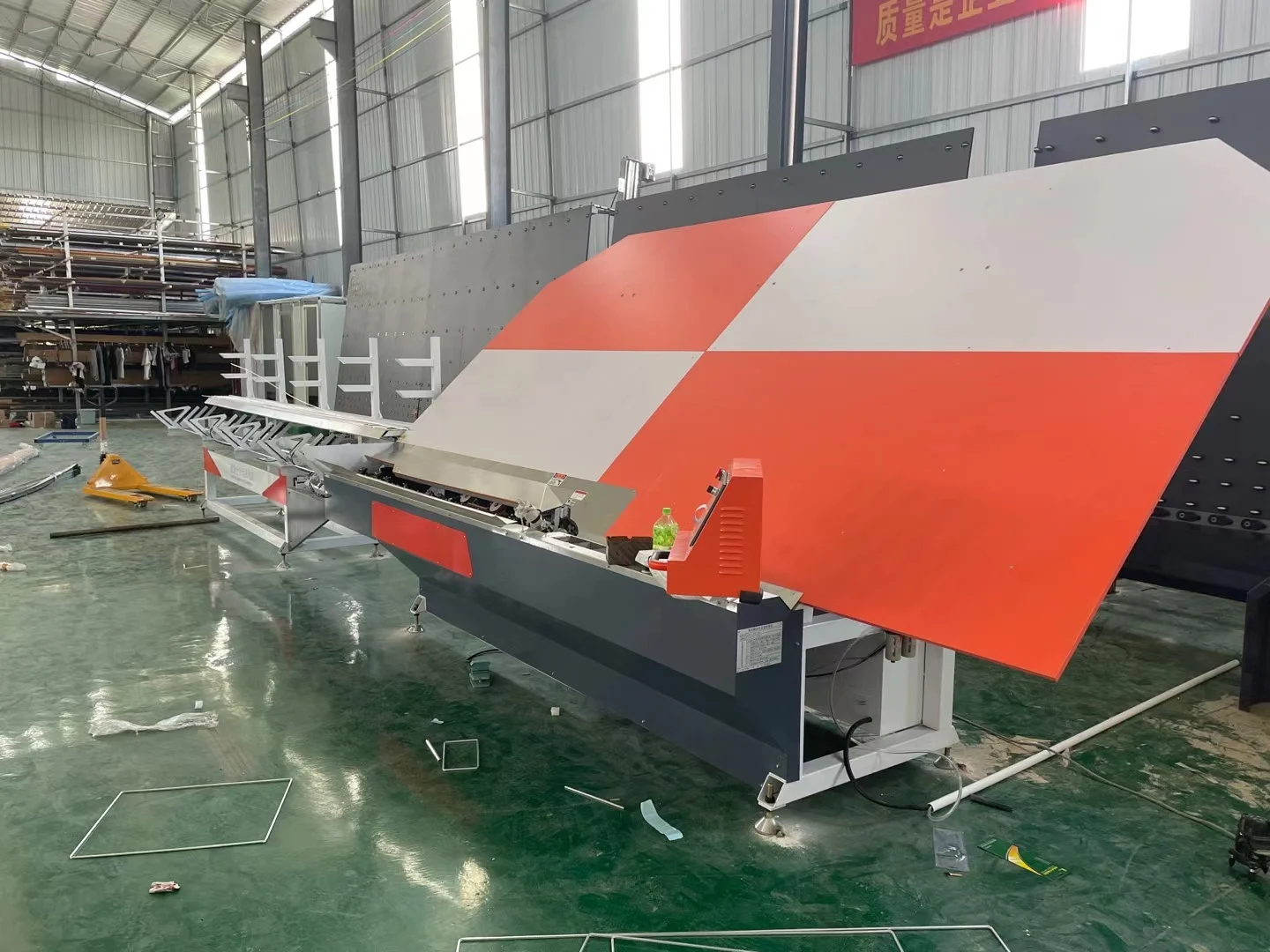

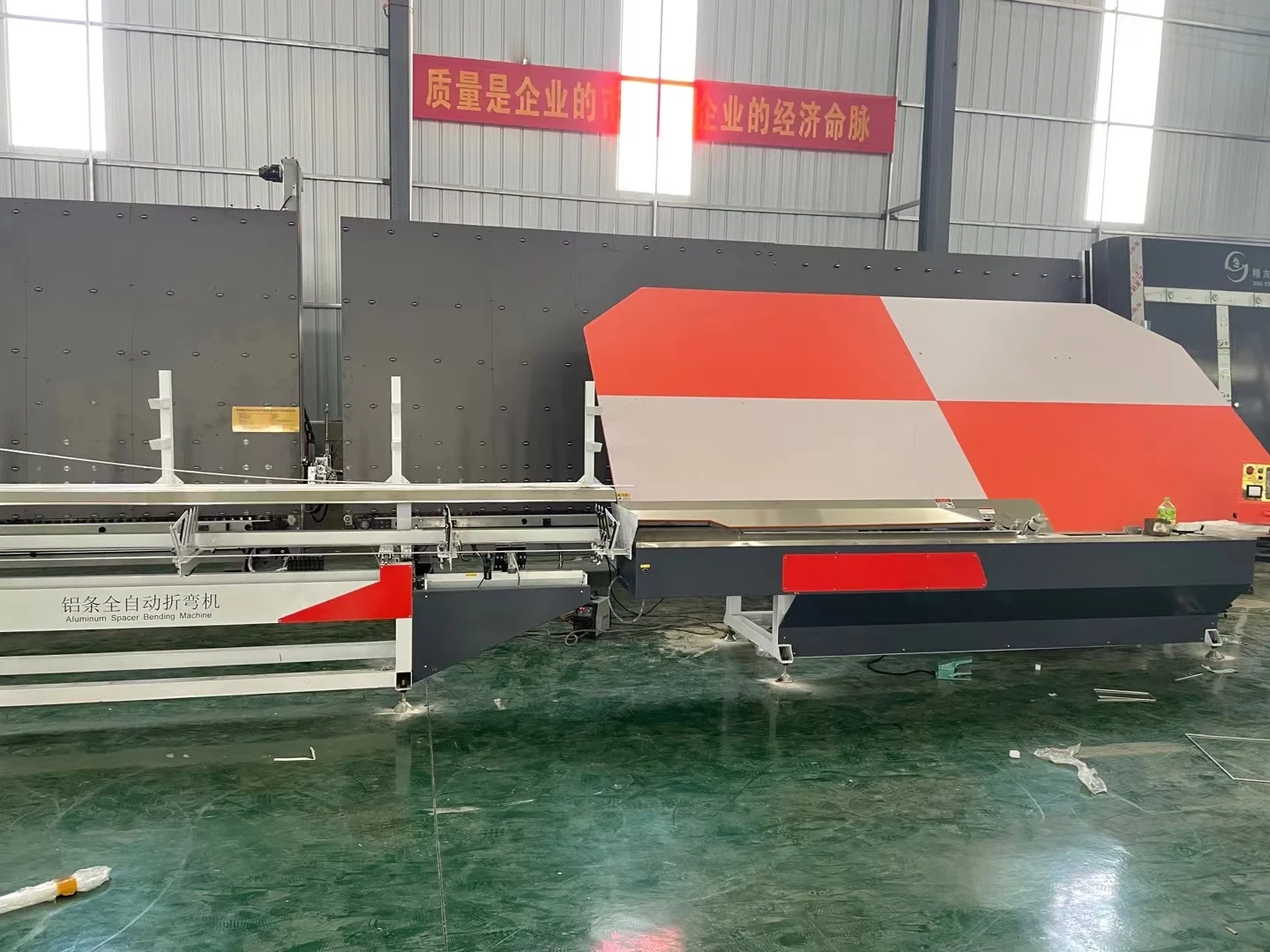

Welcome to our aluminum spacer bending machine, a key piece of equipment for high-precision frame forming in insulated glass production lines. Designed specifically for the forming of aluminum spacer bars, this machine integrates precise positioning, continuous bending, and automatic cutting through an intelligent control system. With stable and reliable forming performance, it ensures accurate frame dimensions and smooth corners, effectively enhancing the sealing performance and structural stability of insulated glass units. Featuring easy operation, stable running, and wide adaptability to different spacer specifications, the machine provides a high-quality frame foundation for subsequent butyl coating and assembling processes, making it an essential equipment for high-end insulated glass manufacturing.

Product Features:

Equipped with PLC control and a touch-screen interface, ensuring simple operation and stable performance.

The feeding system adopts a CNC servo motor, while the bending angle is controlled by a CNC control system, providing high precision and consistency.

Features four material storage slots, allowing automatic selection of four different spacer specifications.

Automatic bending and cutting are integrated to avoid corner connections; cutting is completed automatically after bending, ensuring excellent roundness and dimensional accuracy.

Includes a manual operation mode, making debugging and maintenance easy and efficient.

Capable of producing various shapes such as triangles, rectangles, regular pentagons, regular hexagons, circles, and more.

Equipped with an online label printing device, which prints processing information in real time for improved traceability and production management.

Frequently Asked Questions (FAQ):

Q: What is the delivery time for custom Automatic aluminum spacer bending machine?

A: Delivery time typically ranges from 2 to 3 weeks.

Q: Can the automatic aluminum spacer bending machine be customized?

A: Absolutely! We offer a variety of customization options, including voltage, size, functionality, and electrical components to meet your specific design requirements.

Q: Do you offer installation services?

A: We provide training services for overseas technicians to ensure smooth installation and usage.

Q: What should I do if my machine has an issue?

A: 1) If the machine is under warranty, we can send you free replacement parts. 2) We can send engineers to repair your machine if necessary.