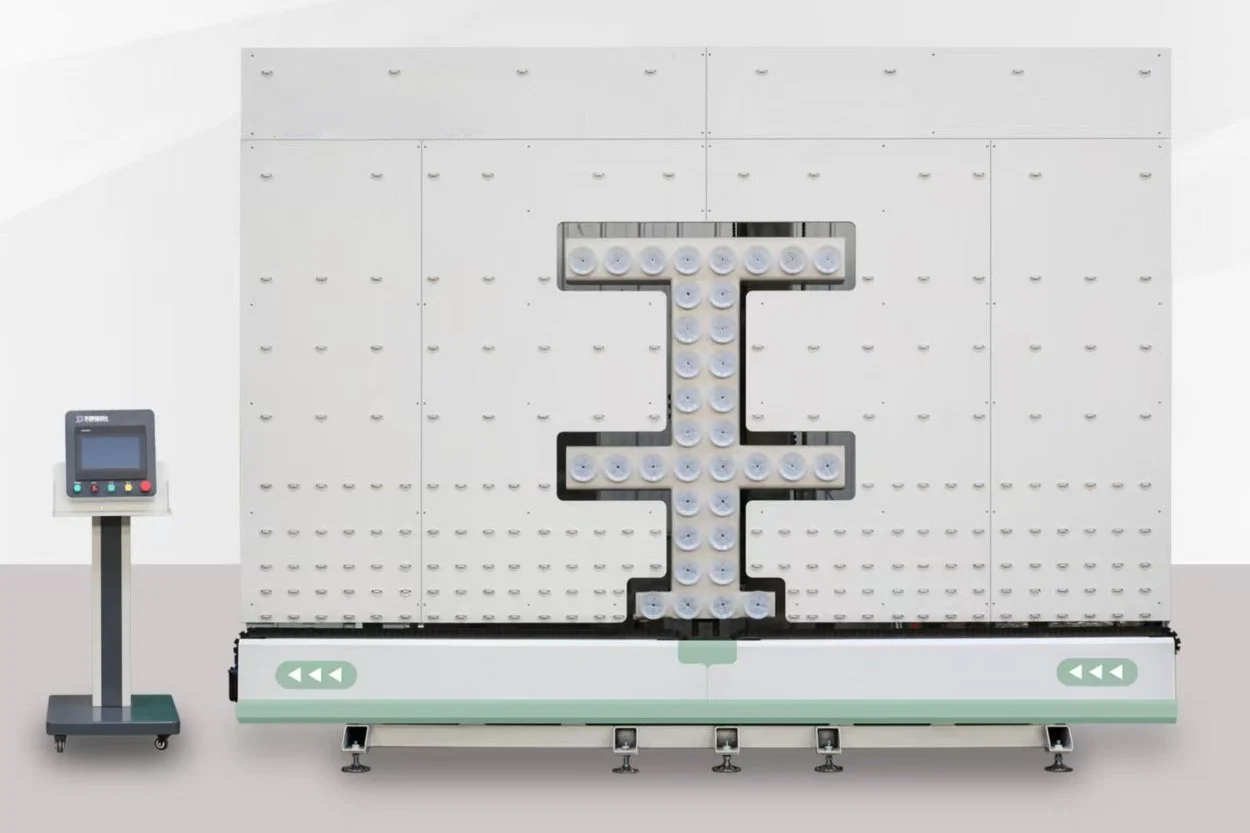

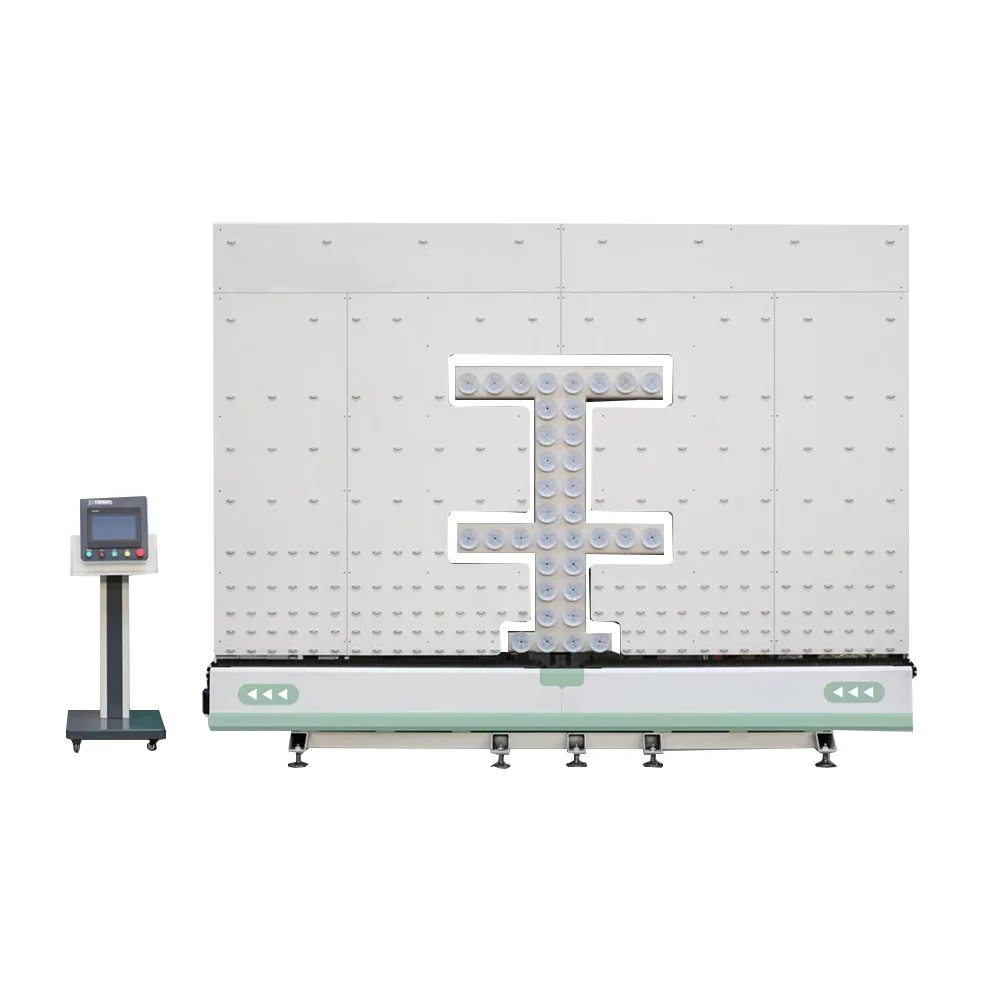

Welcome to our vertical glass loading and unloading machine, a key piece of equipment for safe and efficient glass handling in insulated glass production lines. Designed specifically for glass loading and unloading processes, this machine features a stable vertical structure and an intelligent servo control system, enabling precise positioning, smooth overturning, and automatic conveying of glass panels. With advanced vacuum adsorption and anti-collision control technology, it ensures safe handling, reduces glass breakage, and improves overall production efficiency. Featuring easy operation, stable performance, and high safety, the machine provides reliable support for subsequent washing and assembling processes, making it an essential equipment for high-end insulated glass manufacturing.

Product Features:

Servo overturning system: Uses a servo motor that can stop at any angle with stable running speed, suitable for 3–12 mm glass loading and 10–55 mm insulating glass unloading.

Adjustable tilting angle: The vertical tilt angle is adjustable from 0 to 15 degrees, meeting glass loading requirements from racks at different angles.

Large loading depth: Supports a maximum loading depth of 700 mm, allowing direct loading from the glass rack without any auxiliary frame.

Double-layer vacuum suction system: Adopts an inner and outer double-layer adsorption structure, ensuring firm suction and eliminating air leakage caused by scratches on the outer suction layer.

Lifting and slicing program: Equipped with a unique lifting and slicing control program, enabling smooth and efficient glass separation and unloading.

Flexible operation modes: Supports both automatic and manual modes, with a color LCD touch screen and Chinese display, ensuring intuitive and efficient operation.

Collision prevention design: When the glass rack is too close, the machine extends forward only to a preset position and stops automatically, preventing collision with the conveying rollers during lowering.

Safety protection: Equipped with an emergency stop switch to ensure safe operation in abnormal situations.