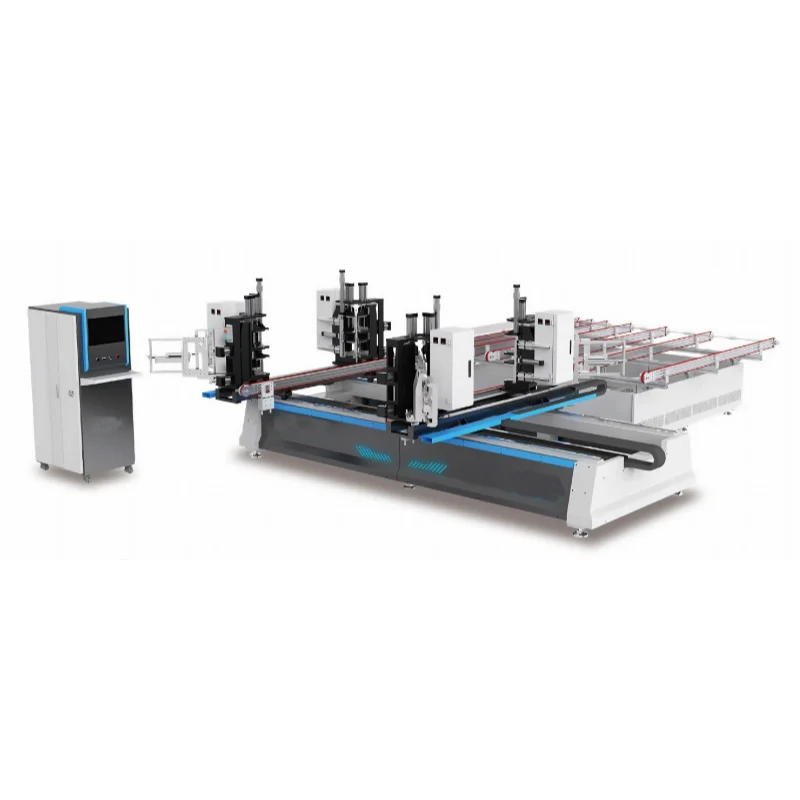

1. This is a specialized machine for four-corner welding of plastic PVC profiles. It features a double-layer design, allowing for the simultaneous welding of two window frames or four rectangular window sashes of profiles under 60mm in height using a spacer plate. The machine feeds materials step by step, layer by layer, and the finished windows are transported to the manual retrieval area via a conveyor table.

2. The machine’s cutting blades are made of high-precision alloy material, precision-machined after heat treatment. The blades are standardized and interchangeable.

3. All moving parts of the machine utilize high-precision linear square guide rails, ensuring the stability and reliability of the equipment.

4. Equipped with a color touch screen and a well-known international CNC system, it drives high-inertia servo motors to automatically complete the welding and transportation of the finished windows. Operation is convenient, and performance is stable and reliable.

5. The XY axes use precision ball screw drives, resulting in fast transmission speeds and accurate processing.

6. The machine frame is welded from thick-walled rectangular steel pipes, providing strong load-bearing capacity and resistance to deformation.

7. Featuring a professional industrial design, the machine perfectly combines practicality with aesthetic appeal, providing customers with a high-end visual experience.