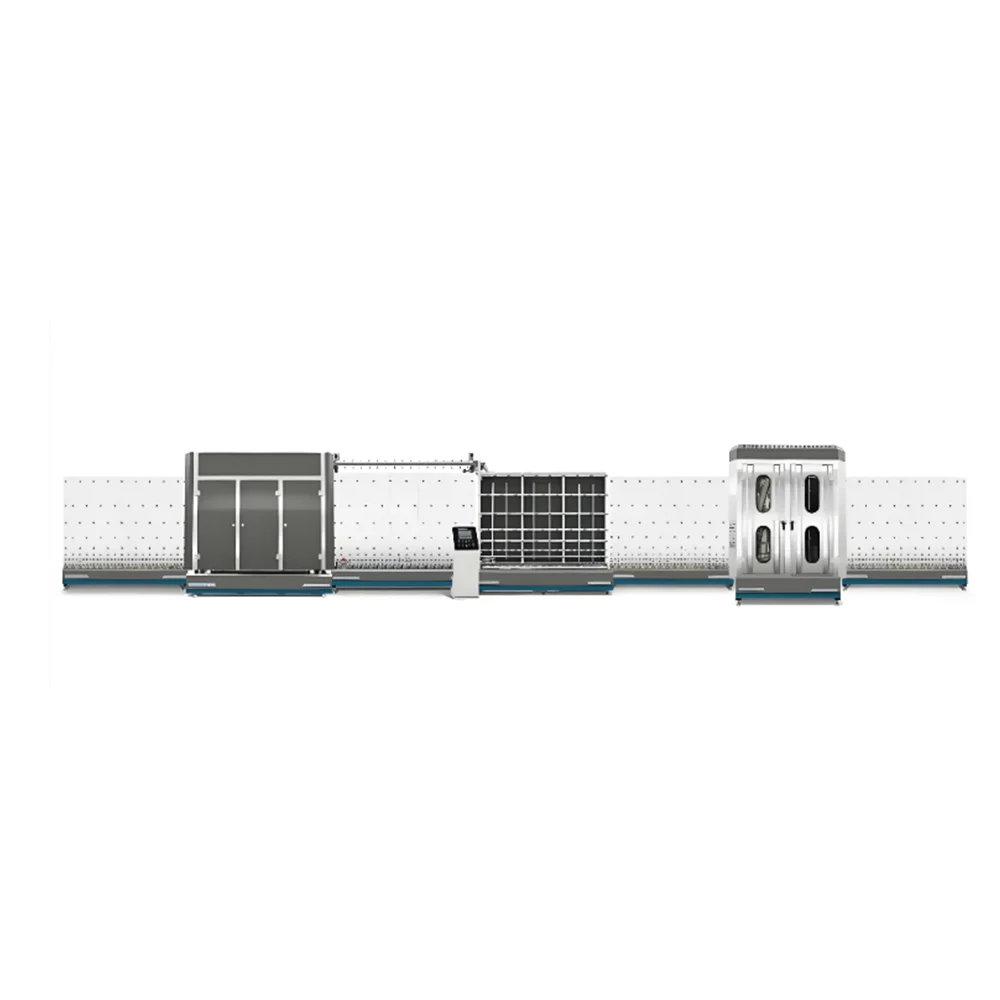

Welcome to our desiccant filling machine, a key piece of equipment for ensuring internal dryness in insulated glass production lines. Designed specifically for the desiccant filling process of aluminum spacers, this machine adopts a stable filling structure and an intelligent control system to achieve precise and uniform desiccant filling. With automatic drilling and quantitative control, it ensures consistent filling volume and even distribution, effectively enhancing the moisture resistance and service life of insulated glass units. Featuring easy operation, stable performance, high efficiency, and low energy consumption, the machine provides reliable support for subsequent butyl coating and assembling processes, making it an indispensable equipment for high-end insulated glass manufacturing.

Product Features:

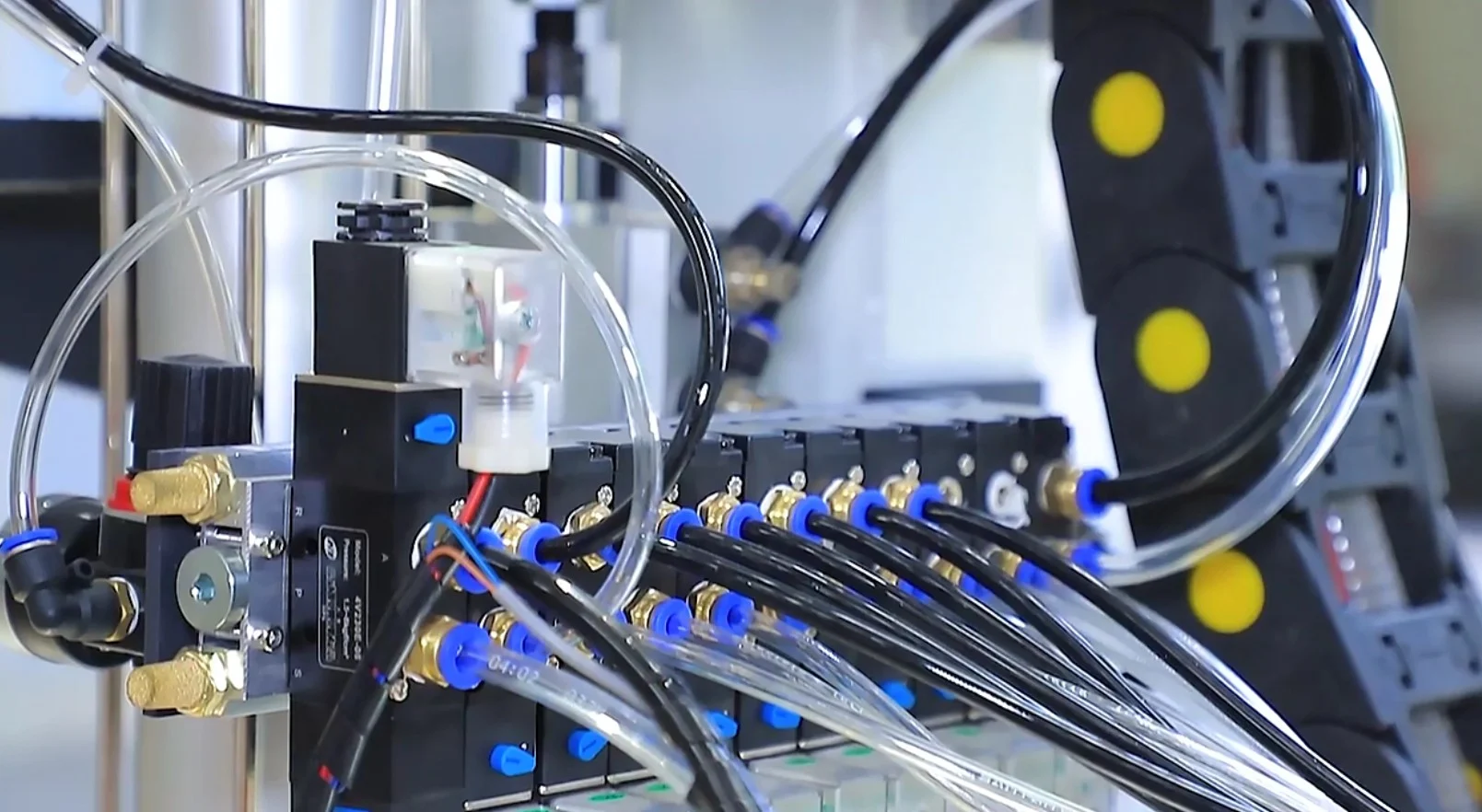

Equipped with a PLC control system and a user-friendly interface, ensuring easy operation and reliable performance.

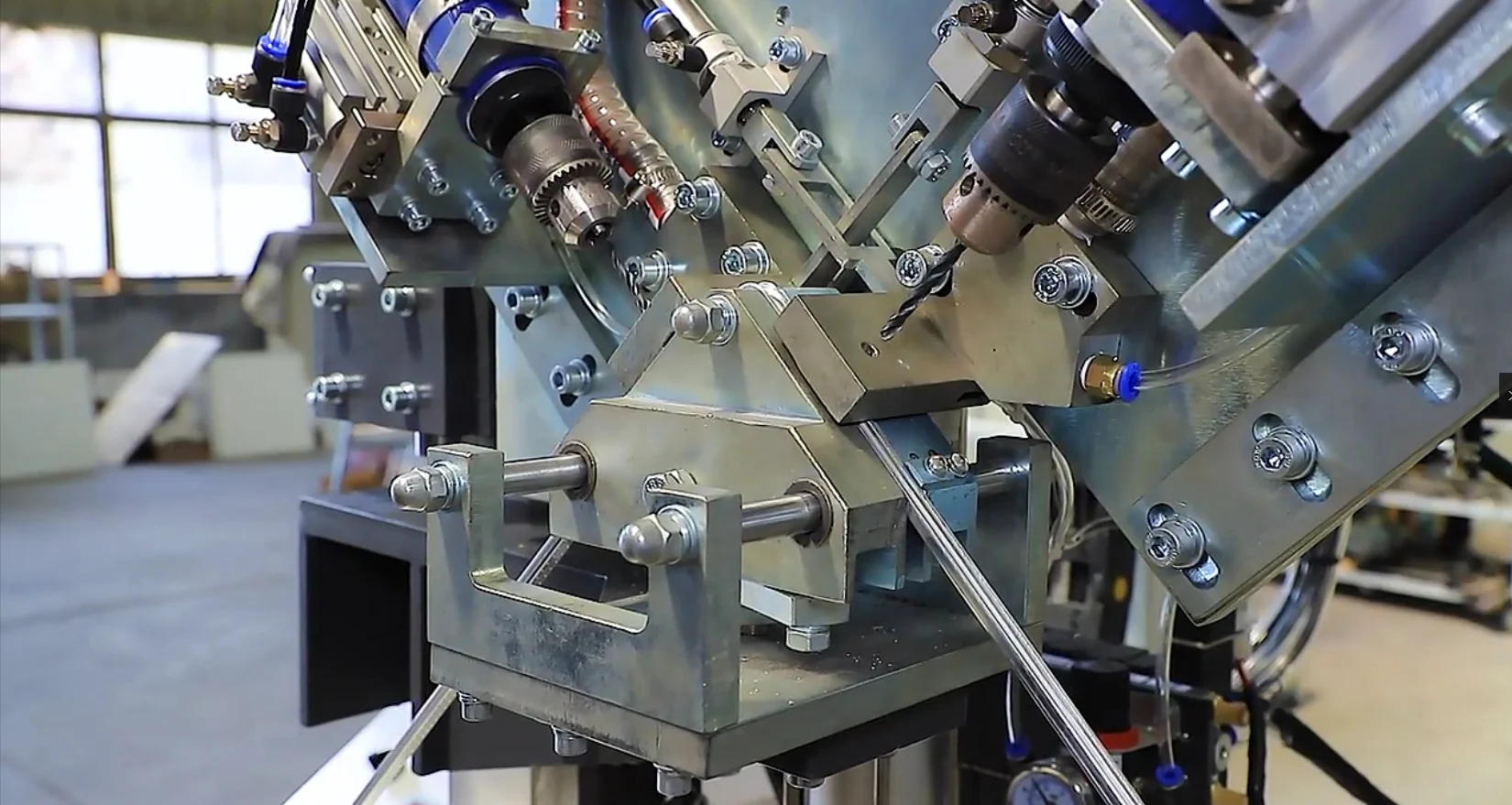

Designed for drilling holes on the backside of aluminum spacers and automatic desiccant filling, improving processing efficiency and consistency.

Key control components adopt imported brand parts, ensuring long-term stability and high reliability.

The machine can be used not only for spacers shaped by an automatic spacer bending machine, but also for ordinary straight aluminum spacers.

The filling volume is adjustable according to different spacer sizes, meeting diverse production requirements.

Features an exclusive and sophisticated feeding device; the storage tank automatically supplies desiccant material as needed, ensuring smooth and continuous operation.