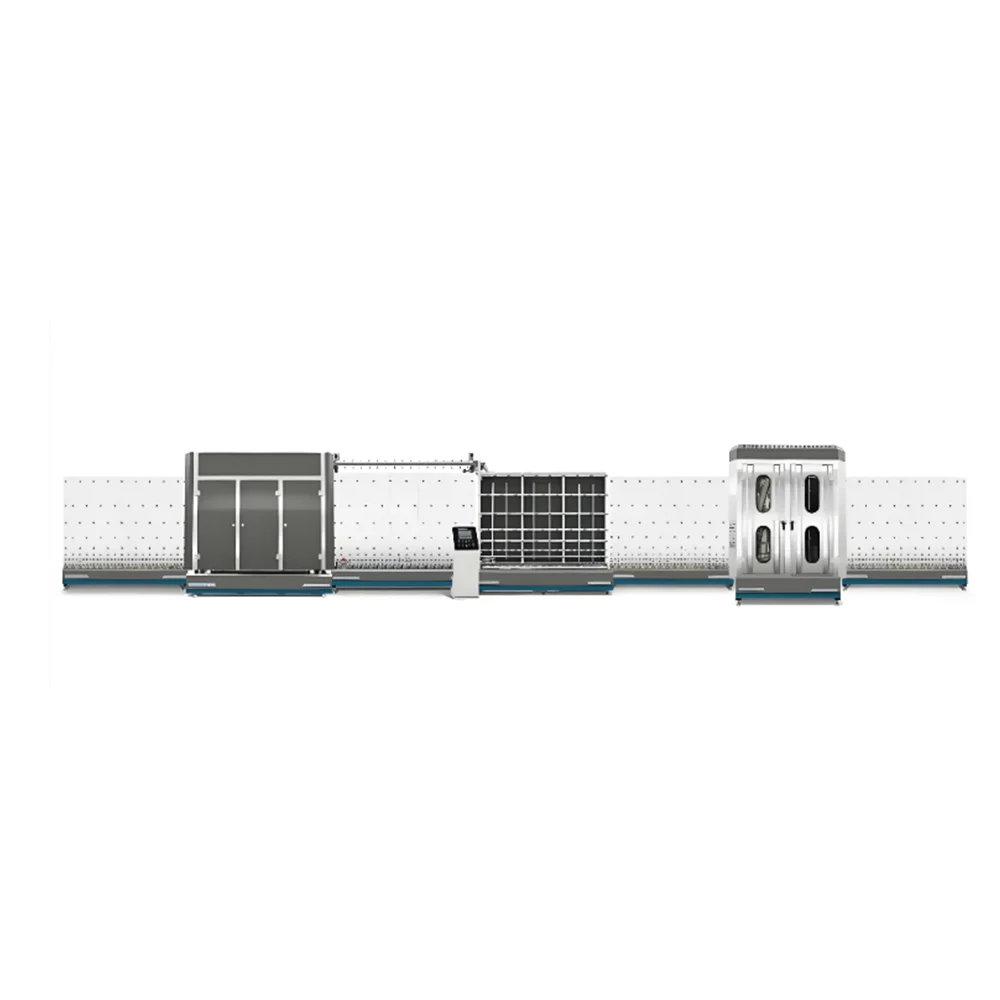

The insulating glass two-component sealing machine is designed for sealing insulating glass units using two-component sealants such as silicone and polysulfide.

With a pneumatic driving system and precise mixing ratio control, it ensures stable dispensing and uniform mixing, providing excellent sealing performance and long service life.

The machine is easy to operate, reliable in operation, and suitable for insulating glass production lines.

Product Features:

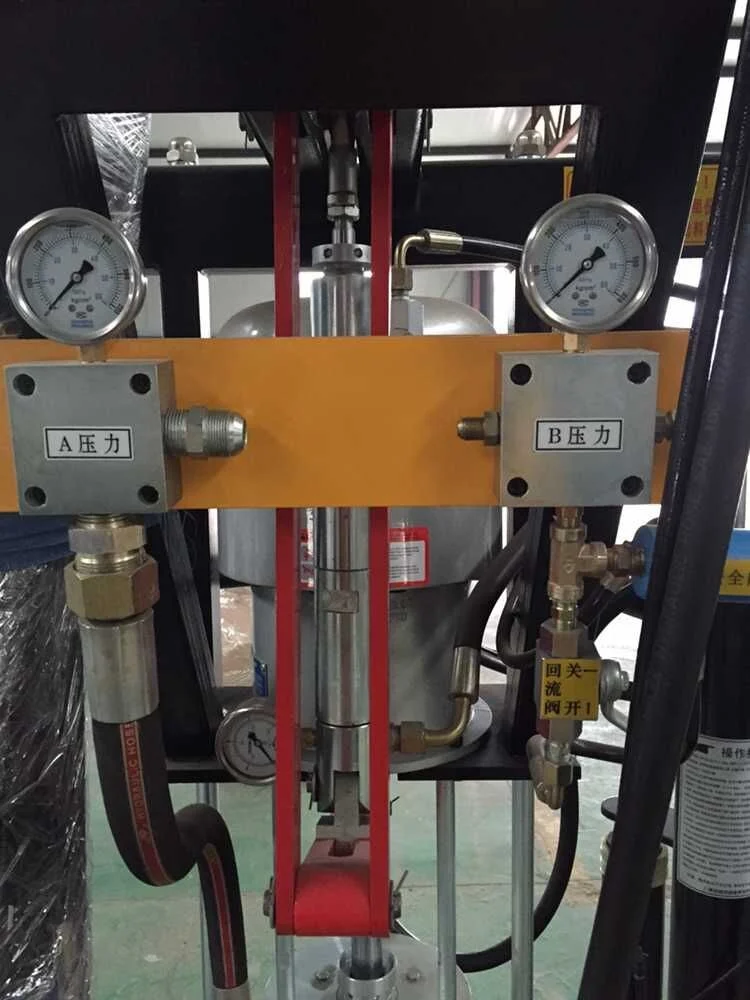

The glue pump for Component A and the pump for Component B (curing agent) are driven by a pneumatic system, providing sensitive and reliable reversing performance.

All mechanical components are made of high-strength stainless steel and undergo a special refining process, which greatly improves the service life of the equipment and ensures stable, high-quality performance.

With an optimized piping layout and an upgraded main motor for higher power output, the machine delivers improved efficiency and stability.

The human-centered control panel and automatic elastic cantilever design make operation simpler, more convenient, and more user-friendly.